Can a Bandsaw Cut Steel

A bandsaw is one of the most versatile tools you can have in a workshop. It can be used to cut wood, plastic, and even metal. But if you’re wondering whether or not a bandsaw can cut steel, then the answer is Yes!

Bandsaws are capable of cutting through various types of metals including stainless steel, aluminum and mild steel. They offer an accurate and efficient way to make straight cuts without having to resort to using more specialized tools such as angle grinders or jigsaws. So if you need to quickly make precise cuts in any type of metal material, then investing in a good quality bandsaw should definitely be considered.

Bandsaws come with many different features that help them stand out from other saws when it comes down to making these kinds of cuts. For example they usually feature a wider blade than regular saws which makes it easier for them to handle thicker materials like steel without much difficulty compared with other saws like jigsaws or circular saws which may struggle under the same conditions due their thinner blades and less powerful motors respectively.

When it comes to cutting metal, a bandsaw is one of the most popular tools for getting the job done. But can a bandsaw cut steel? The answer is yes!

A bandsaw has the ability to cut through many types of metal, including steel.

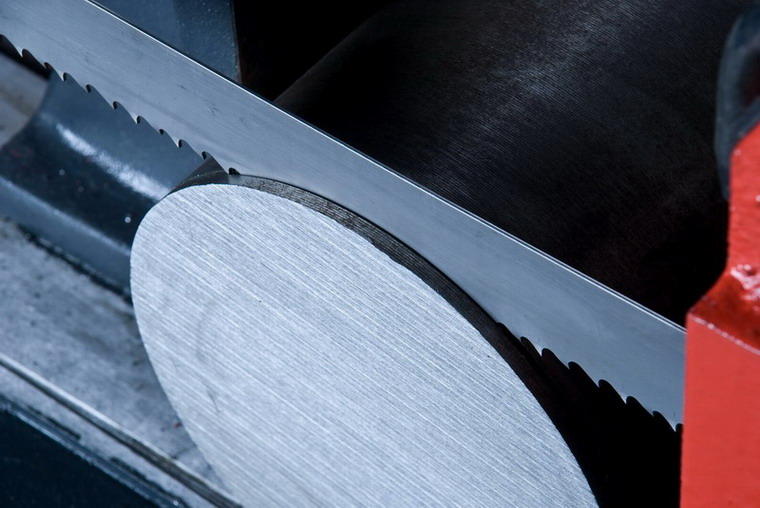

This type of saw uses an endless looped blade that moves in an up-and-down motion and cuts with both vertical and horizontal strokes. This makes them ideal for precision cutting on metals such as aluminum, stainless steel, and mild steel.

They’re also great for making intricate curves and shapes in softer materials like wood or plastic.

So how do you use a bandsaw to cut steel? Firstly, make sure your band saw is properly set up before attempting any cuts – this includes checking the tension on the blade so it doesn’t break while cutting as well as ensuring that all adjustments are made correctly according to manufacturer guidelines.

Next choose the appropriate blade size based on what thickness of material you need to cut – generally speaking thicker blades will be best used for thicker materials while thinner blades can handle thinner pieces more easily without buckling under pressure from too much resistance during operation. Finally adjust your speed settings depending on how thick or thin you need your piece(s) to be sliced – slower speeds are recommended when dealing with harder materials since they require more time per revolution (which leads less chance of breakage).

Overall using a bandsaw is convenient way to make clean precise cuts through steels (as well as other metals) quickly and efficiently but just remember practice safety first by always wearing protective gear such as gloves, goggles, dust masks etc… Happy Cutting!

Credit: www.detroitbandsaw.com

Can I Use My Bandsaw to Cut Metal?

If you’re looking for an answer to the question “Can I use my bandsaw to cut metal?,” the short answer is yes. It’s important, however, that you understand what types of metals are appropriate for cutting with a bandsaw as well as how to safely and efficiently operate your machine.

A bandsaw is a type of saw used in woodworking and metalworking.

It typically has two wheels connected by an endless loop of flexible metal blade that rotates around them at high speeds. This allows it to make intricate cuts in various materials such as wood, plastic, and some metals like aluminum or brass. However, using a bandsaw on harder metals like steel can be tricky due to their thickness and durability.

When it comes to cutting metal with your bandsaw, there are certain factors you need take into consideration before starting any project:

1) Choose the Right Blade – Selecting the right blade for your particular material is key when attempting this task because different blades will better suit different types of metals (e.g., thinner blades for softer materials). A bi-metal blade designed specifically for cutting ferrous (iron/steel) materials should work best if you’re planning on working with steel or other hard metals.

2) Keep Your Work Area Clear – Before beginning any cuts with your band saw, make sure there are no obstacles near or around the area where you plan on making them; this includes people who can potentially get injured from flying debris created during operation which could include small pieces of hot shrapnel traveling at high speeds! Additionally, if possible try keeping walls away from where chips may fly out—this way they won’t be damaged either during projects so they remain safe in case anything goes wrong while using your saws frame or motor itself needs repair down line later on down time period after usage happens too much then might need replacing instead .

3) Use Coolants When Possible – Using coolants when attempting tough cuts will help keep both your tooling temperatures lower than usual; this reduces friction between surfaces which means less heat build up over longer periods ensuring more efficient operations overall throughout entire job duration especially when dealing w/harder alloys like stainless steels etc..

Additionally applying lubricant oils also helps reduce wear tear & extends life span even further depending upon brand quality chosen wisely beforehand accordingly responsibly always !

4) Take Safety Precautions – Finally but most importantly always utilize necessary protective equipment such goggles , gloves & masks before beginning any heavy duty jobs just incase worst case scenarios arise unexpectedly without warning suddenly all at once sooner rather than later unfortunately … Nothing beats having proper safeguards place beforehand preventing potential accidents injuries happening worse off yet even death eventually God forbid really happened tragically anytime soon ever hopefully not indeed !!

In conclusion – Yes! You can use a band saw to cut metal provided that safety precautions have been taken and all relevant specifications regarding blades and operation have been met correctly properly firstly lastly foremost only afterwards shall one proceed confidently knowing full well risks involved prior being aware informed beforehand taking necessary steps avoid unnecessary problems arising up shortly thereafter next basically speaking… Good luck out there everyone stay safe above else enjoy yourselves whilst doing so too!!

Can You Cut Steel With a Wood Bandsaw?

Many people often ask whether it is possible to cut steel with a wood bandsaw. The short answer is yes, but there are several considerations you should take into account before attempting this tricky task.

The first and most important factor when cutting steel with a wood bandsaw is the type of saw blade you use.

Wood blades will not be suitable for cutting metal, as they are too soft and will become quickly worn down or even break under the pressure of cutting through steel. Instead, you must use either a bimetal or carbide-tipped blade specifically designed for metalworking applications if you want to successfully cut through steel using your wood bandsaw.

Another consideration is that while many wood band saws have adequate power and speed capabilities to handle the tougher job of slicing through metal, some may not be powerful enough depending on their size and motor capacity.

If your saw isn’t up to snuff in this area then it won’t have enough torque to push its way through thicker pieces of steel without bogging down or stalling out completely mid-cut.

It’s also important to note that when working with metal on any kind of machine tool, safety should always come first! Wear appropriate safety gear such as eye protection, gloves, long sleeves/pants/shoes etc., make sure your workspace is clean and well lit so that you can clearly see what you’re doing at all times; never leave tools unattended when running; keep children away from the work area; unplug machines after each use; avoid reaching over moving parts; properly secure workpieces before beginning operations – these are just some basic tips which apply whenever working in close proximity with potentially dangerous machinery like a band saw!

Additionally, consult manufacturer instructions for further guidelines related to specific models in order for best results (and safest practices) when tackling projects involving metalworking applications on a wood band saw machine tool setup.

In conclusion then: Yes – it’s definitely possible to cut steel using a wood band saw – provided however that proper precautions have been taken (including choosing an appropriately rated blade plus following necessary safety protocols). As always though – exercise caution accordingly whenever considering taking on DIY tasks which involve operating any kind of potentially hazardous equipment!

Can a Bandsaw Cut Hardened Steel?

Bandsaws are one of the most versatile tools in a woodworker’s arsenal, able to make intricate cuts with ease. But can they be used for cutting hardened steel? The answer is yes – but it’s not as straightforward as you might think.

Hardened steel is incredibly strong and difficult to cut through with traditional saw blades. In order to successfully cut through this type of material, you need a specialized bandsaw blade that has been specifically designed for the job. These blades are made from high-speed steel (HSS) or tungsten carbide, both of which have superior strength and durability compared to standard blades.

Additionally, these specialty blades feature an aggressive tooth pattern that helps them penetrate harder materials more easily than standard ones would.

When using a bandsaw blade on hardened steel, it’s important to keep in mind several key factors:

-The speed at which the blade moves must be kept constant throughout the entire cutting process; too slow or too fast will cause problems such as excessive wear or breakage of the teeth on the blade.

-Using lubricant will help reduce friction between the two surfaces and prevent heat build-up during use; this also helps extend the life of your saw blade significantly by preventing premature dulling or breakage due to overheating.

-The feed rate should be adjusted depending on how thick and hard your material is; if it’s very thick, then slower speeds should be used so that there isn’t any chance of breaking off chunks from your workpiece while trying to cut through it quickly.

Overall, when done correctly and safely, bandsaws can certainly be used for cutting hardened steel – though it does require some special considerations compared to working with regular metals like aluminum or brass.

If you decide that this type of sawing project is right for you, make sure that you invest in quality HSS/carbide blades and take all necessary safety precautions before getting started!

Can I Put a Metal Blade in a Band Saw?

If you’re considering putting a metal blade in your band saw, it is important to understand the potential risks and benefits associated with this decision. While many people opt for a wood-cutting blade when working with their band saws, there are some scenarios where using a metal cutting blade can be advantageous.

To begin with, let’s start by talking about the differences between wood-cutting blades and metal-cutting blades for use in band saws.

Wood-cutting blades typically feature larger teeth that are set at wider angles than those found on metal-cutting blades. This allows them to create smoother cuts in softer materials like wood. Metal-cutting blades have smaller teeth that are usually set at sharper angles – allowing them to cut through harder materials such as metals or plastics more efficiently while producing very clean cuts and minimal burrs (the rough edges left behind after cutting).

When it comes to safety, there are both advantages and disadvantages associated with using a metal cutting blade in your band saw. On one hand, they can be far more efficient than traditional woodworking blades; however they also require much greater attention to detail during setup and operation due to their tendency to vibrate significantly more than standard woodworking Blades. Additionally, because of the sharpness of these blades they pose an increased risk of injury if proper precautions aren’t taken – such as wearing appropriate safety gear like gloves when handling them or ensuring that all moving parts are securely fastened before beginning work.

Overall, if you choose to use a metal cutting blade for your project make sure you take all necessary safety precautions beforehand and ensure that your hands remain away from any spinning parts during operation! You should also consider investing in an anti kickback device which will help reduce the chances of kickbacks occurring if something gets caught up inside the machine while it’s running – potentially saving you time (and fingers) down the road!

Can You Cut Steel On A "Wood Cutting" Bandsaw?

What is a Good Band Saw for Cutting Metal

If you’re in the market for a new band saw to cut metal, there are a few important considerations that should be taken into account. Not all band saws are created equal, so it’s important to find one that will meet your specific needs and budget.

When selecting a good bandsaw for cutting metal, the first thing you should consider is what type of blade material is best suited to the job at hand.

Carbon steel blades tend to last longer than other types of blades when cutting through hard materials like metals, while bi-metal or high-speed steel (HSS) blades offer increased durability and better performance on softer metals such as aluminum or brass. Additionally, some band saws come with replaceable tips which can help extend their lifespan if they become worn down over time from regular use.

The size of the bandsaw is another important factor to consider when looking for a good option for cutting metal; larger machines will generally provide more power and accuracy during cuts but may require additional space in your workspace.

It’s also worth noting that certain models may feature variable speed settings which can be beneficial when working with various types of metals as they allow you to adjust the speed depending on the thickness or hardness of each material being cut.

Finally, safety features are an invaluable component when searching for any type of power tool – this especially holds true with band saws due to their sharp blades and powerful motors; look out for features like adjustable guards/covers and emergency stop buttons which ensure optimal user protection while operating these tools safely at all times..

Ultimately finding a good band saw specifically designed for cutting metal requires careful consideration – by evaluating factors such as blade composition, size & power output along with necessary safety features, you can make sure you select an appropriate model tailored exactly towards your project requirements without compromising on quality or performance!

Conclusion

Sure, a bandsaw can cut steel! Whether you’re looking to make straight cuts or intricate curves in mild steel or alloy steel, a standard metal-cutting bandsaw is up for the challenge. Just be sure to use blades designed specifically for cutting metal and ensure that your saw is equipped with an adequate motor size and blade speed range.

With the right setup, you’ll be able to tackle projects ranging from hobbyist applications like custom knife making to industrial-grade production runs. If your project requires very precise cuts, however, consider investing in an automated machine like a band saw mill as these units come with more sophisticated features such as hydraulic vise control and adjustable stroke length settings which will yield highly accurate results every time. No matter what you need it for – whether it’s hobby work or production—a good quality bandsaw can do the job when it comes to cutting through tough metals like steel.