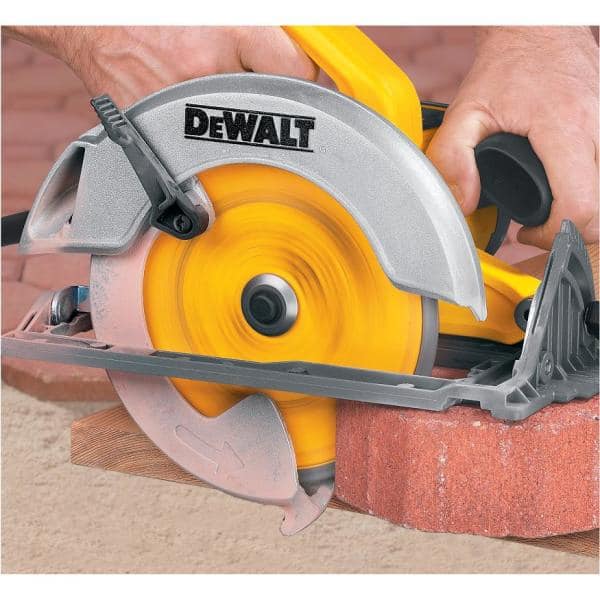

Can I Put a Diamond Blade on a Circular Saw

A diamond blade is a powerful tool for cutting hard materials such as masonry, stone, and concrete. Often used in construction or industrial applications, these blades make quick work of tough jobs. But can you put a diamond blade on a circular saw?

The answer is yes! Putting a diamond blade on your circular saw can provide the perfect solution to some of those difficult DIY projects around the home. With the right combination of power and precision, you’ll be able to cut through materials like cement board and ceramic tiles with ease – all while keeping yourself safe from harm!

This blog post will explore how to safely install and use a diamond blade on your circular saw so that you can get started with your own projects at home.

- Prepare the Saw: Make sure that the saw is unplugged and placed on a stable surface

- Check to see if it has an adjustable blade guard and remove any debris from around the arbor nut or flange area of the saw

- Place Blade on Spindle: Carefully place blade with teeth facing down onto the spindle, lining up both blades slots with tabs found on either side of saws arbor nut or flange

- Secure Blade to Saw: Firmly secure blade by tightening arbor nut or flange using an appropriate size wrench before turning on power switch for circular saw

- 4

- Test Run: Plug in circular saw and slowly start motor, allowing for adequate time for blade to reach full speed before attempting operation or cutting action with diamond blade installed

Credit: www.homedepot.com

Can You Use a Circular Saw to Cut Stone?

No, you cannot use a circular saw to cut stone. A circular saw is designed to make cuts in wood and other soft materials such as plastic or aluminum. Stone is too hard for it, so if you want to cut stone with a power tool you need something more powerful like an angle grinder or a masonry saw.

An angle grinder is the most common tool used to cut stone because it’s relatively inexpensive, easy to handle and can make precise cuts. Angle grinders are typically powered by electricity or compressed air and have diamond-tipped blades that can easily slice through even the toughest materials like granite and marble. The downside of using an angle grinder for cutting stone is that it generates quite a bit of dust, so be sure to wear eye protection when operating one of these tools.

A masonry saw uses either wet or dry diamond blades specifically designed for cutting through hard stones like granite and marble. These types of saws produce much less dust than angle grinders but they tend to be expensive and require more setup time before use (such as filling up a water basin). If you’re planning on doing multiple projects involving stonework then investing in this type of power tool might be worth your while since it will save you time in the long run due to its efficiency at making clean cuts with minimal effort required from the user’s end.

So no matter what kind of project involving stonework you want to tackle, using the right equipment makes all the difference when trying achieve precise results quickly without any extra mess caused by dust particles flying around everywhere! Always remember safety first though – regardless which type of power tool you decide on using, always follow its instructions carefully and never forget protective gear such as goggles/glasses!

Can I Put a Concrete Blade on Circular Saw?

If you’re looking for a way to make precise cuts in concrete, tile and masonry materials, then using a circular saw with a concrete blade may be the perfect solution. But can you really put a concrete blade on your average circular saw? The short answer is yes!

With the right tools and safety precautions, it is possible to use a regular circular saw with an appropriate diamond-tipped or abrasive blade to cut through hard materials like concrete.

When choosing which type of blade will work best for your project, there are several factors that come into play. First off, diamond-tipped blades are typically better suited for cutting through harder materials such as stone and brick while abrasive blades work well when cutting softer material such as wood or plastic.

Additionally, different sizes of blades will provide different results depending upon the size and shape of the material being cut. When considering what size of blade to use for cutting concrete surfaces, consider that larger blades tend to reduce vibration during operation resulting in smoother cuts than smaller ones do.

Safety should always be your top priority when working with power tools so wearing protective gear like goggles and gloves is essential whenever using any kind of power tool including those equipped with special concrete blades meant specifically for this purpose.

Also ensure that all parts used – from the base plate down to each individual screw – are made from corrosion resistant steel designed specifically for this type of job in order avoid damaging either yourself or the machine itself due to rusting components over time.

In summary if you have need precision cuts in hard materials like stone or brick then putting an appropriate sized diamond tipped or abrasive blade on your ordinary circular saw could be just what you need get those jobs done efficiently – just make sure you take proper safety precautions first!

Can You Use Any Blade in a Circular Saw?

If you’re a DIYer or professional contractor, having the right tools for the job is essential. One of those tools that can be used in many situations is a circular saw. But what about blades?

Can you use any blade in a circular saw? The short answer is yes, but there are some things to consider before doing so.

First and foremost, it’s important to understand that different blades will produce different results when used with a circular saw.

While all blades are designed to cut wood, certain blades are better suited for specific tasks than others. For example, thin-kerf blades will create less waste and require less power from your tool while standard kerf blades provide greater stability during cutting operations but could result in more material being wasted if not set up correctly. Additionally, carbide-tipped blades offer longer life and sharper edges than regular steel ones while specialty diamond-tipped or titanium-coated models may be necessary for particularly difficult materials like stone or concrete products.

It’s also important to make sure the size of your chosen blade matches the arbor size (the hole where the blade attaches) on your particular model of circular saw so that it fits securely in place without wobbling around during use which can cause kickback and potential injury hazards as well as poor quality cuts due to lack of stability. Make sure you check both outer diameter measurements as well as inner diameter measurements before purchasing any new accessory pieces such as an additional arbor or adapter sleeve – these items should match up precisely with existing components on your machine otherwise they won’t work properly together!

Finally, always wear appropriate safety gear such as eye protection while using any type of power tool including circular saws regardless of what type of blade is installed onto them; this includes gloves too!

It’s always best practice to double check everything prior to turning on any motorized device just incase something isn’t quite right – don’t risk getting injured by taking shortcuts here!

In conclusion, yes it is possible to use various types of blades with a circular saw depending on what kind project you need done but do take into account factors like size compatibility and safety first before attempting anything else with this powerful piece machinery!

Can I Use a Grinder Blade in a Circular Saw?

The short answer to this question is no, you cannot use a grinder blade in a circular saw. In fact, using any type of grinding tool or blade in a circular saw can be extremely dangerous and should never be attempted.

A grinder blade is designed for the specific purpose of grinding down metal or other hard materials while a circular saw blade is designed to cut through wood with precision and accuracy.

The material that makes up the blades are different; grinders usually have diamond-tipped carbide bits while saw blades are made out of steel with sharp teeth at the edges. Additionally, each tool has its own motor which spins the respective blades at different speeds – grinders typically operate around 8500 revolutions per minute (RPMs) whereas most circular saws run between 5500 and 6000 RPMs.

Using an incompatible blade such as a grinder’s in your circular saw could cause it to overheat quickly due to increased friction from trying to rotate faster than it was built for, leading to catastrophic failure and potentially causing serious injury or damage if used improperly.

It could also cause kickback – where the material being cut suddenly jumps back towards you instead of following its intended path – which can cause serious harm if not handled properly.

In conclusion, using any kind of grinding tool or blade in place of the designated one on your circular saw isn’t just ill-advised but downright hazardous and should never be done under any circumstances! If you need something more powerful than what your standard saw can offer then look into investing in another power tool like an angle grinder that’s specifically designed for that type of job – trust us when we say it’ll be worth it!

7-1/4 Circular Saw Masonry Blade

If you’re looking to make quick work of masonry projects, a 7-1/4 Circular Saw Masonry Blade is an essential tool for the job. It’s a high-powered blade designed specifically to cut through brick, concrete and other hard materials with ease. With the right blade, you can make clean cuts in seconds without having to worry about overworking your saw or damaging your material.

When it comes to choosing a masonry circular saw blade, there are several key factors that need to be considered before making a purchase. First and foremost is size – the diameter of the blade should match up with that of the saw itself (7-1/4 inch for this particular model). It also helps if the teeth on the blade have been sharpened properly – sharper blades will produce better results than dull ones every time.

The number of teeth per inch (TPI) also makes a difference as more teeth means smoother cuts but less speed; conversely fewer teeth will yield quicker cuts but rougher edges in return.

The type of material you’ll be cutting should also factor into which kind of 7-1/4 Circular Saw Masonry Blade you choose as well; some blades are meant for softer materials such as brick and mortar while others feature carbide tips designed specifically for tougher jobs like concrete or stone cutting. Finally, check out what kind of coating has been applied onto each side: one side should usually be nonstick so debris won’t build up while working while another may come with an anti-friction layer designed to reduce heat buildup during operation.

In conclusion, investing in quality tools such as a 7-1/4 Circular Saw Masonry Blade can help make any project go much smoother and faster than ever before! Be sure to research all available options thoroughly before selecting one so that it meets your specific needs best – happy shopping!

Conclusion

If you’re looking for a powerful, versatile tool to cut through masonry or tile, then you may be wondering if it’s possible to put a diamond blade on your circular saw. The answer is yes! A diamond blade can be attached to virtually any type of circular saw and is great for cutting through tough materials like stone, concrete, brick and more.

However, there are some important safety considerations that must be taken into account before making the switch. Make sure you use the right type of blade and wear proper eye protection when using your circular saw with a diamond blade attachment. With the right precautions in place, you’ll enjoy all the benefits that come with having one of these powerful tools in your arsenal.