Bandsaw Blade Stops When Cutting

When you’re cutting with a bandsaw, the last thing you want is for your blade to stop in the middle of the cut. Unfortunately, this can happen for a variety of reasons. The good news is that it’s usually easy to fix the problem so you can get back to cutting.

If you’re having trouble with your bandsaw blade stopping while you’re cutting, there are a few things you can check. First, make sure that the blade is installed correctly and that the tension is correct. If the blade is installed incorrectly or if it’s not properly tensioned, it can cause the blade to stop while you’re cutting.

Another thing to check is the alignment of the blade. If the blade isn’t aligned properly, it can also cause the blade to stop while you’re cutting. To check the alignment of the blade, use a straightedge to see if the teeth of the blade are lined up with the slot in the saw’s table.

If they’re not lined up properly, adjust them until they are.

Finally, make sure that there’s nothing obstructing the path of the blade. Sometimes debris can get caught between the teeth of the blade and cause it to stop.

If you find anything blocking the path ofthe blade, remove it and try again.

Band Saw Blades

Band saw blades are one of the most important tools in any woodworking shop. They come in a variety of sizes and shapes, each designed for a specific purpose. The right blade can make all the difference between a successful cut and a ruined piece of wood.

There are three main types of band saw blades: carbon steel, high-speed steel, and bi-metal. Carbon steel blades are the cheapest and most common type. They’re also the least durable, so they’re not ideal for heavy-duty cutting jobs.

High-speed steel blades are more expensive, but they stay sharp longer and can handle tougher cuts. Bi-metal blades are the most expensive, but they’re also the strongest and most durable type.

When choosing a band saw blade, it’s important to consider what material you’ll be cutting most often.

Softwoods like pine and cedar require different blades than hardwoods like oak and maple. You should also think about the thickness of the material you’ll be cutting; thicker pieces require wider blades.

Once you’ve selected the right blade for your needs, it’s time to install it on your saw.

Most band saws use 6″ or 8″ wheels, so you’ll need to match those sizes when purchasing your blade. If you’re not sure how to install the blade, consult your owner’s manual or watch a few tutorial videos online before getting started. With proper care and maintenance, your band saw blade will last for years to come!

Credit: www.rockler.com

Why Does My Bandsaw Keep Jamming?

There are a few reasons your bandsaw might be jamming. The first reason is that the blade might be dull. When blades get dull, they can’t cut through wood as easily and will often get stuck.

If you think your blade might be dull, try replacing it with a new one.

Another reason your bandsaw could be jamming is because the tension on the blade isn’t tight enough. If the tension is too loose, the blade can start to wobble and will eventually get stuck in the wood.

To fix this, make sure you tighten the tension knob until the blade is snug but not too tight.

The last reason your bandsaw might be jamming is because there is something caught in between the teeth of the blade. This can happen if you’re cutting through knots or other hard objects in the wood.

To fix this, simply remove the object from between the teeth and continue cutting.

If you’re having trouble figure out why your bandsaw keeps jamming, take it to a professional for help.

How Do I Know If My Bandsaw Blade is Tight Enough?

If your bandsaw blade is not tight enough, it can cause the blade to slip off the wheel while in use. This can be dangerous and cause injury. Here are a few things to look for to make sure your bandsaw blade is tight enough:

1. Check the tension knob to make sure it is turned all the way clockwise.

2. Look at the blade itself. If it is loose on the wheel, it needs to be tightened.

3. Try moving the blade back and forth. If there is any movement, it needs to be tighter.

4. Finally, check with a tuning fork or other similar tool.

Place it next to the band saw blade while it is running.

How Much Tension Should a Bandsaw Blade Be?

Bandsaw blades come in a variety of widths and thicknesses, so it’s important to choose the right blade for your saw and your particular project. The thickness of the blade will determine how much tension the blade can handle without breaking. For example, a 1/2-inch wide blade can handle up to about 12,000 pounds of tension, while a 3/4-inch wide blade can handle up to 18,000 pounds of tension.

When it comes to setting the tension on your bandsaw blade, it’s important to err on the side of caution. If you’re not sure how much tension is safe for your particular blade, start with a lower setting and gradually increase the tension until you reach the desired level. Remember that too much tension can cause the blade to break, so always err on the side of caution when adjusting the tension on your bandsaw blade.

Should You Release the Tension on Bandsaw?

Bandsaws are one of the most versatile tools in a woodshop. They can be used to rip lumber, cut curves and even make intricate scrollsawn patterns. But like any tool, they need to be properly maintained to stay in good working order.

Part of that maintenance is knowing when and how to release the tension on the blade.

If you’re not sure whether or not you should release the tension on your bandsaw, here are a few things to keep in mind:

-The type of material you’re cutting: Softer woods like pine can be cut with less tension than hardwoods like oak.

If you’re unsure, err on the side of less tension. You can always add more if needed.

-The thickness of the material: The thicker the piece you’re cutting, the more tension you’ll need to apply to the blade.

Again, if you’re unsure, start with less tension and increase as needed.

-The width of the cut: Wider cuts require more tension than narrower ones. If your saw isn’t cutting cleanly or seems to be struggling, try releasing some tension from the blade.

Generally speaking, it’s best to err on the side of less rather than more when it comes to tensioning your bandsaw blade. If in doubt, release some tension until you find the sweet spot that works for your particular project.

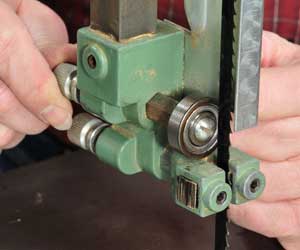

Bandsaw slipping fix

Conclusion

If your bandsaw blade stops while you’re cutting, it’s likely due to one of three things: the blade is dull, the blade is damaged, or the blade is not installed correctly. A dull blade will cause the saw to slow down and eventually stop; a damaged blade can also cause the saw to stop abruptly. If the problem is with the installation, be sure that the blade is tight and that all of the teeth are pointing in the same direction.