Millionaire Guide About Can I Cut Tile With a Circular Saw

When it comes to tiling projects, a circular saw is often seen as an invaluable tool. This type of saw is versatile and can ensure accurate cuts that are essential for any tile installation project. But many people wonder whether they can use a circular saw to cut tiles or if this could damage the tile itself or the blade of the saw.

The answer is yes—you can cut tile with a circular saw as long as you take certain precautions and use the right kind of blade for cutting ceramic, porcelain, stone, or other types of tiles. To begin with, make sure you have selected a diamond-tipped blade specifically designed for cutting ceramic and masonry materials such as tile; these blades are thicker than standard blades due to their hard metal core which makes them ideal for cutting through tougher surfaces like ceramic tiles without damaging them in the process. Additionally, be sure to select a lower RPM (revolutions per minute) setting when using your circular saw so that you don’t inadvertently cause too much heat buildup in the blade while it is spinning at high speed against harder surfaces such as tiles.

- Step 1: Gather the necessary materials for the job. This includes a circular saw, tile blade, safety goggles, gloves, measuring tape, and marking pen or pencil

- Step 2: Measure and mark where you want to cut the tile with a marking pen or pencil. Make sure that your measurements are accurate before proceeding

- Step 3: Put on your safety gear including goggles and gloves to protect yourself from debris while cutting the tile

- Step 4: Securely attach a diamond-tipped tile blade to your circular saw according to the manufacturer’s instructions. Make sure it is firmly attached so it will not come off during the operation of the saw

- Step 5: Place the marked section of the tile onto a flat surface such as a workbench or sawhorse before making cuts into it with your circular saw. This will help avoid any slipping when cutting through tough material like ceramic tiles which can be very brittle if not handled properly

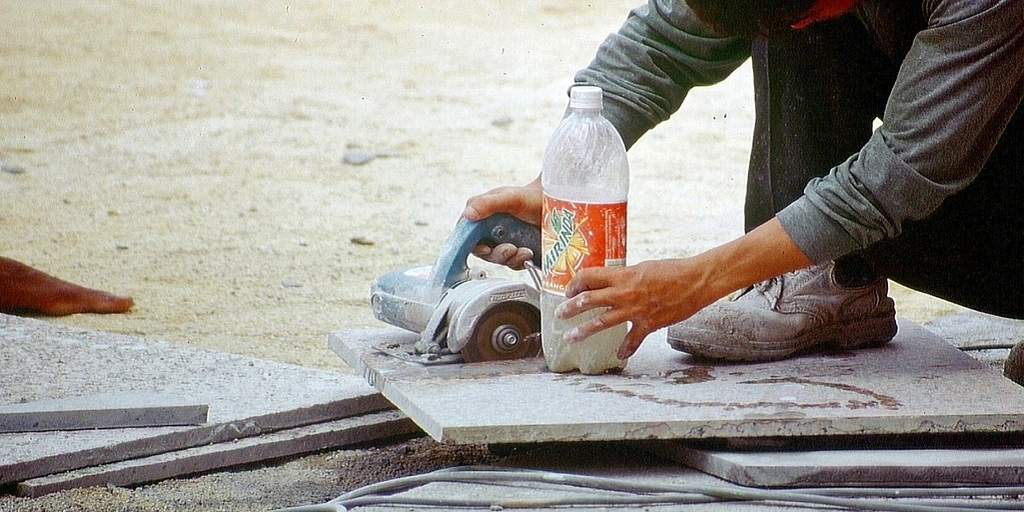

- Step 6: Use light pressure when pushing down on your circular saw against the marked area of tile in order to make an initial cut into it without putting too much strain on either yourself or the equipment being used for this project

- Step 7: Follow along with previously made markings by slowly moving back and forth over them until the desired shape has been achieved for each piece of cut-out material

Can You Cut Tile Without a Wet Saw?

Tile cutting is a task that requires precision, and most DIYers will want to get the job done as quickly and efficiently as possible. But what happens when you don’t have access to a wet saw? Is it still possible to cut tile without one?

The answer is yes! While there are many advantages of using a wet saw for tile cutting (including cleaner cuts, less chipping, and better accuracy), there are several different methods you can use if you don’t have access to one. Here are some of the best ways to cut tile without a wet saw:

1. Manual Tile Cutter: A manual tile cutter is an inexpensive tool that uses two metal bars with scoring wheels in between them. This allows you to score your tiles before snapping them along the scored line with pliers or nippers. Manual tile cutters work best on straight lines but may struggle with curved shapes or intricate designs.

2. Angle Grinder: An angle grinder fitted with a diamond blade can be used effectively for cutting ceramic tiles; however, this method does produce dust so make sure you wear protective gear such as goggles and breathing masks when operating this type of tool. The advantage here is that angle grinders provide much more precise results than manual tile cutters do – perfect for those tricky curves!

3. Hammer & Chisel: If all else fails then hammering and chiseling away at your tiles will eventually get the job done – although it’s not exactly accurate nor particularly neat! Make sure you wear safety glasses while doing this as well as heavy-duty gloves so your hands don’t get damaged from any flying shards of the ceramic during the process!

4 . Table Saw With Diamond Blade: If none of these options suits your needs then consider investing in a table saw equipped with a diamond blade attachment specifically designed for tiling jobs – just be aware that they tend to cost quite a bit more than other tools mentioned here so make sure it’s worth the investment before taking out your wallet!

Can I Put a Diamond Blade on a Circular Saw?

Yes, you can put a diamond blade on a circular saw. Diamond blades are designed to cut through tough materials like concrete and stone that would be difficult or impossible to cut with conventional blades. The advantage of using a diamond blade is that it will last longer than other types of blades and provide much smoother cuts.

When installing the diamond blade onto your circular saw, there are some important things to consider in order to ensure safe operation and good cutting performance. First, make sure the arbor size of your saw matches the arbor size of the diamond blade; otherwise, it won’t fit properly and could cause damage or injury during use. Additionally, check for any instructions about mounting included with your specific model as each manufacturer may have different recommendations for installation.

It is also important to note that not all circular saws accept diamond blades due to their larger diameter compared to standard wood-cutting blades. Therefore it’s best practice to double-check before purchasing one for use with your particular saw model in order to avoid potential compatibility issues. Furthermore, since they generate an immense amount of heat while cutting hard materials like tile or granite, cooling systems such as water sprays should be used when operating them. This helps keep both the machine components and operator safe from excess heat build-up which could lead to serious injuries if neglected over time due to excessive wear & tear on parts or burns respectively.

Finally, always wear proper safety gear such as goggles when working with power tools regardless if they contain regular/specialty type-blades – this goes without saying but is often overlooked by many DIYers who underestimate how dangerous these machines can actually be despite their small form factor! By following these simple tips you can make sure you get optimal performance out of your newly installed diamond blade on your circular saw without risking personal harm in doing so!

Can Any Saw Cut Tile?

Tile is an essential material used in a variety of projects around the home, from bathrooms and kitchens to patios and outdoor living areas. Many homeowners are opting for tile as their go-to flooring option due to its durability, versatility, and stylish look. However, many are left wondering if any saw can cut tile.

The answer is yes! Any saw can cut tile with proper preparation. Depending on the type of saws you use. Such as a jigsaw or wet saw you will need to make sure it’s properly equipped for cutting tile.

For example, if you plan on using a jigsaw for your project then it should have carbide-tipped blades specifically designed for cutting through ceramic or porcelain tiles. If you’re using a wet saw then be sure that the blade is rated for both dry and wet applications so that it won’t overheat when making cuts in damp conditions. When preparing to cut your tiles there are some important safety considerations worth noting before getting started: always wear eye protection when operating power tools; secure your workpiece firmly onto the table surface; set up guides such as clamps or straight edges along the line where you want to make your cuts; keep fingers away from moving blades; never force materials into the tool path; be mindful of sparks generated by metal blades hitting hard surfaces like stone or porcelain tile during operation, and take extra care when working with larger pieces of machinery such as angle grinders which can cause serious injury if mishandled.

Now that we know any saw can cut tile let’s talk about what kind of results they produce under different circumstances: – A standard jigsaw typically works well on thin wall tiles (less than 1/4 inch thick) but generally isn’t recommended for thicker substrates like a natural stone because these require more powerful equipment capable of producing precise cuts without chipping away at delicate edges – Wet saws may be more expensive but they cleanly slice through all types of ceramic, porcelain, glass mosaic and even certain types of granite effortlessly within minutes – plus they don’t create dangerous dust particles in enclosed spaces like dry models do

– Angle grinders excel at cutting curved shapes into smaller pieces however this method comes with increased risk since sparks created by metal blades striking hard surfaces could lead to damage to surrounding properties – Diamond core bits offer fast drilling speeds while producing smooth edges ideal for intricate designs yet their cost makes them less desirable unless precision detailing is needed No matter which type of application best fits your project needs – whether its manual labor via hand tools or powered options utilizing diamond-tipped drill bits – one thing holds true across all scenarios: Proper preparation prior to beginning ensures successful results each time!

Can You Cut Tile With a Dry Saw?

If you’re looking for a way to cut tile quickly and easily, then a dry saw may be the perfect tool for the job. A dry saw is a handheld electric tool that can be used to easily and accurately cut tile into any shape or size you need. Dry saws are becoming increasingly popular among DIYers because they offer quick, precise cuts without having to use messy wet-cutting methods.

Dry saws use either diamond blades or carbide-tipped blades in order to make clean and accurate cuts on ceramic, porcelain, marble, granite, slate, and other hard materials such as glass tiles. When cutting with a dry saw it is important to use special water-resistant lubricants so that the blade does not overheat while cutting through your material. The biggest benefit of using a dry saw is that there is no mess involved!

You won’t have to worry about constantly cleaning up after yourself when working with wet-cutting methods like masonry grinder wheels or angle grinders because there isn’t any water or slurry created by this process. When cutting tiles with a dry saw it’s important that you wear proper safety equipment such as goggles and gloves since flying pieces of tile can cause serious injury if not taken seriously. Additionally, keep in mind that depending on what type of material you’re trying to cut (i.e., thicker materials like stone will require more power from your motor) you’ll want to make sure your motor has enough power otherwise it could lead too slow/uneven cuts which could ruin the entire project!

Also, remember never to force the blade through materials; always go slowly in order to achieve the best results possible! Overall using a dry saw has many advantages when compared to traditional wet-cutting tools making them ideal for anyone who needs precision cuts without all of the mess associated with other tools available on market today! So next time you’re looking at starting up a new tiling project consider investing in one – it just might save you time energy (and money!) down the road!

5 Ways to Cut Tile – Everything You Need to Know for Your First Tile Project

Tile Blade for Circular Saw

If you’re a DIYer or contractor who’s looking for the right saw blade to use on tile, then look no further than the tile blade for a circular saw. Tile blades are designed specifically to cut through tough ceramic and porcelain tiles with ease. They feature an incredibly sharp diamond-tipped edge that allows them to easily slice through even the hardest of materials without causing chipping or breakage along the edges.

Even better, these blades come in various sizes so you can find exactly what you need for any project. When it comes time to shop for a tile blade, there are several factors that should be taken into consideration before making your purchase. First off is size – make sure you get a blade that’s large enough for your particular project as well as one that fits your saw properly.

You also want to ensure it has enough teeth per inch (TPI) so it won’t create too much friction when cutting through tiles; typically, anything from 4 TPI up will suffice depending on how thick and dense your material is. Additionally, take note of its arbor size since this will determine which type of saw can use it – either 5/8″ or 1″ arbor holes work best with most models out there today! It’s important to keep in mind that not all tile blades are created equal – some may contain softer metal than others and therefore dull quickly while others might have an abrasive coating applied which can cause more damage over time if used improperly.

To avoid potential issues down the line, research different brands thoroughly before deciding which one works best for you! Lastly, always wear protective eye gear when working with a circular saw as flying debris and dust particles could potentially cause injury if they hit unprotected eyes directly! Tile blades provide an efficient way of slicing through hard materials like ceramic or porcelain tiles quickly and cleanly – leaving behind perfectly smooth edges every single time!

With proper care & maintenance these tools should last many years giving their owners plenty of quality cuts each goes around; just remember though not all options available on market today offer the same level of performance so do thorough research beforehand in order to ensure a success rate once begins tackling projects at home or job site alike!

Conclusion

Yes, you can cut tile with a circular saw! All you need is the right blade and safety gear. A diamond-tipped blade designed for cutting ceramic tile or porcelain tile will allow you to easily make straight cuts in your tiles.

When using a circular saw, be sure to wear protective glasses and gloves, as well as a dust mask to protect yourself from any airborne particles produced by the saw. Additionally, ensure that your work area is clear of obstacles and that the floor beneath your project is covered with something like newspaper or drop cloths in order to catch any bits of debris created while cutting the tile. Finally, make sure that your saw is securely mounted on a stable surface before beginning so it doesn’t move around when you’re cutting.

With these tips in mind, now all that’s left to do is get out there and start making those perfect cuts!

2 Comments